Cosmetic Tubes: Layers and Characteristics of Tubes

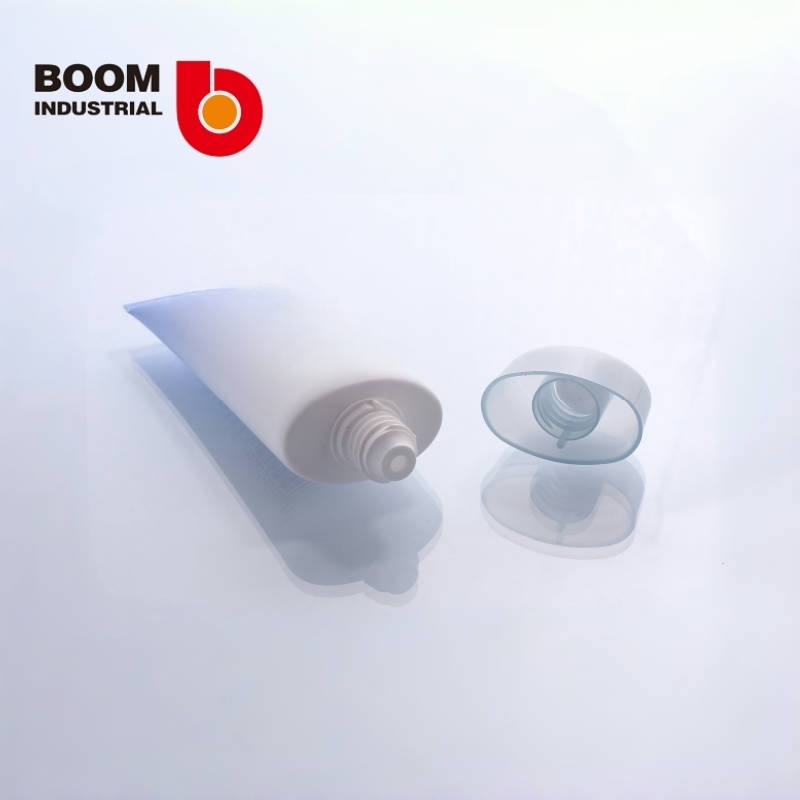

1. Tubes: These are divided into double-layer, five-layer, and six-layer tubes, each of which excels in terms of pressure resistance, permeability resistance, and tactile feel. They are one of the most widely used cosmetic packaging options on the market today.

Features: Good plasticity, simple manufacturing process, and diverse production methods. Effectively prevents oxidation and permeability.

Tube diameter: 10–60 mm, capacity: 3–400 ml. The length and diameter of the tube can be customized. Appropriate capacity and tube length can be selected based on actual requirements to ensure a harmonious appearance.

This technology is divided into round tubes, flat tubes, and ultra-flat tubes. Flat tubes and ultra-flat tubes are more complex than round tubes, with more production processes, so their prices are correspondingly higher.

2. Caps: Soft tube caps come in various shapes, generally categorized into screw caps, flip caps, double-layer caps, ball caps, spout caps, and pump head caps. They can also be processed through various techniques such as edge sealing, electroplating, spraying, water treatment, transfer printing, and anodized aluminum.

3. Tube Sealing: Sealing types are diverse, including arched seals, irregular seals, asymmetrical seals, and other shaped seals, enhancing product uniqueness.

4. Cosmetic tubes can also be used for surface treatments such as bark texture, soft-touch finish, iridescent pearlescent, and rubber paint finish.

5. The production cycle for cosmetic tubes is generally around 30 days (from sample tube confirmation), with a minimum order quantity of 10,000 units. Some smaller factories may have lower minimum order quantities.

6. Mold customization: Mold customization is a service offered by large factories, while small factories generally lack the capability to provide this service. The mold customization process typically involves the following steps: (customer proposes design concept → provides product drawings → repeated communication and confirmation of product drawings → creation of 3D prototype → design of complete mold drawings → mold production after drawing confirmation → mold testing and small-batch trial production → provision of test data and samples, with the physical product as the final reference, until the customer accepts the mold).

Quality Policy: Continuous improvement, striving for excellence.

Environmental Policy: Comply with laws and regulations, prevent pollution. Reduce waste and energy consumption, involve all employees, and pursue continuous improvement.

Occupational Health Policy: Emphasize safety, prioritize prevention, prioritize people, strengthen supervision, pursue continuous improvement and compliance with laws, ensure health and safety every day, and achieve mechanization, automation, and intelligence in production processes to significantly improve production efficiency and quality.

Specific Applications of Cosmetic Packaging Materials Specific Applications of Cosmetic Packaging Materials

Personalized packaging for cosmetic tubes can enhance a product’s influence. Packaging can also add value to an ordinary product and influence market development. Ziyutang Daily Chemical Packaging Products will now introduce the specific applications of cosmetic packaging materials.

Cosmetic packaging materials are divided into inner packaging materials and outer packaging materials. Generally, cosmetic manufacturers provide drawings or general requirements, and the production is entirely handled by the packaging material supplier. However, some cosmetic packaging materials require more detailed specifications based on specific circumstances and requirements, such as partial printing, bottle packaging materials, and bottle body packaging materials. Cosmetic packaging materials include glass, which is used for cream bottles, serums (glass bottle body + plastic pump head or electroplated aluminum pump head), and toners. Essential oil bottles (glass bottle body + inner stopper + large cap or rubber dropper + dropper + electroplated aluminum cap). For glass cosmetic packaging materials, the production of bottle bodies requires coating, including transparent bottles, frosted bottles, and colored bottles. Additionally, white porcelain bottles and essential oil bottles are not commonly colored but have high order volumes.

Cosmetic packaging materials also include plastic, which is used for tubes (tubes + outer caps/tubes made of PE plastic), cream bottles, serum bottles, water bottles, pump heads, and outer caps. Plastic bottle bodies are directly produced as colored plastic products, with colored options being more common and transparent ones less so. Printing methods include screen printing, offset printing, and hot stamping (gold or silver).

How to select the most suitable cosmetic tubes

Many people have noticed that while cosmetics are now widely popular, the tubes used for them have also become a focus for cosmetic manufacturers. As a result, cosmetic tubes have begun to attract the attention of numerous companies. How to select the most suitable plastic tubes for cosmetics has become a key concern for many businesses.

When selecting such cosmetic tubes, procurement personnel from various companies should not only focus on the tube manufacturer or price, as these are important considerations. The tubes themselves also require thorough understanding. When considering tubes, one will find that they have begun to be categorized into various types, such as single-layer or double-layer tubes, which can meet the needs of different cosmetics.

Furthermore, when researching cosmetic tubes, one will find that these tubes also vary in material, such as plastic tubes and PE tubes. The differences in material are applied to different cosmetics, so this aspect is worth considering, especially given the importance of material selection today.

For companies with current needs, when selecting cosmetic tubes, plastic tube manufacturers must consider various factors, particularly the material and classification of the tubes. Only after thoroughly understanding these aspects can they purchase suitable tubes.