laminate tubes

Introduction

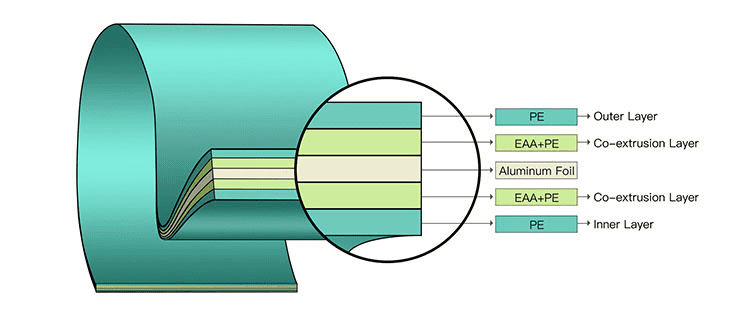

Laminated tubes are formed by rolling a flat sheet into a cylinder and welding two sides of the sheet together. Laminate tubes are a hybrid of aluminium tubes and plastic tubes. They efficiently protect contents thanks to many overlaid layers, one of which is the barrier layer.Usually barrier layers are made of aluminium or EVOH plastic. Laminate tubes, with their multi-layer structure, provide excellent barrier properties that help prevent loss of flavors, preserve essential oils and minimize the transmission of oxygen, gas and light to maintain product stability.It is because of these great barrier features that laminate tubes are becoming increasingly popular for food applications. They are also used for a growing list of packaging pplications including pharmaceutical, cosmetic and industrial uses as well as artist aints.

Our Laminate Tube Variety

ABL tubes

(Aluminum Barrier Laminate)

There are two variants:

ABL tubes (Aluminum Barrier Laminate)

PBL tube (Plastic Barrier Laminate)

ABL tubes have a thin aluminum layer inserted in-between the plastic layers

to protect contents. The result is a plastic metallic tube that meets the

requirements of high-quality pharmaceutical and cosmetic products. ABL

tubes are the #1 barrier layer tube with extraordinary Oxygen Transmission

Rate (OTR) and Water Vaper Transmission Rate (WVTR) properties.

PBL tube

(Plastic Barrier Laminate)

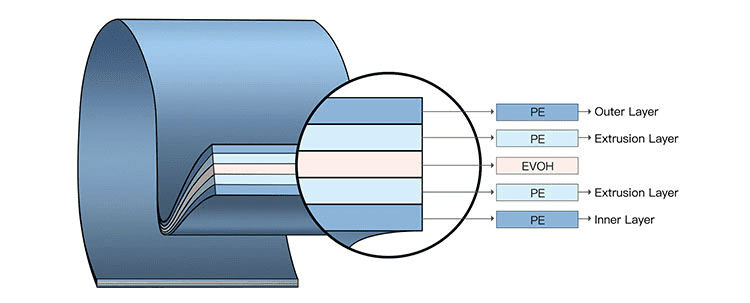

PBL tubes are all-plastic laminate tubes without any aluminum. PBL

laminate tubes have several layers, one of which is the EVOH (Ethylene

Vinyl Alcohol) barrier layer to protect the tube’s contents for maximum

shelf life.

While providing great graphic opportunities and great

barrier properties, this tube retains its shape for the life of the

contents.

Laminate Tube

Production Process

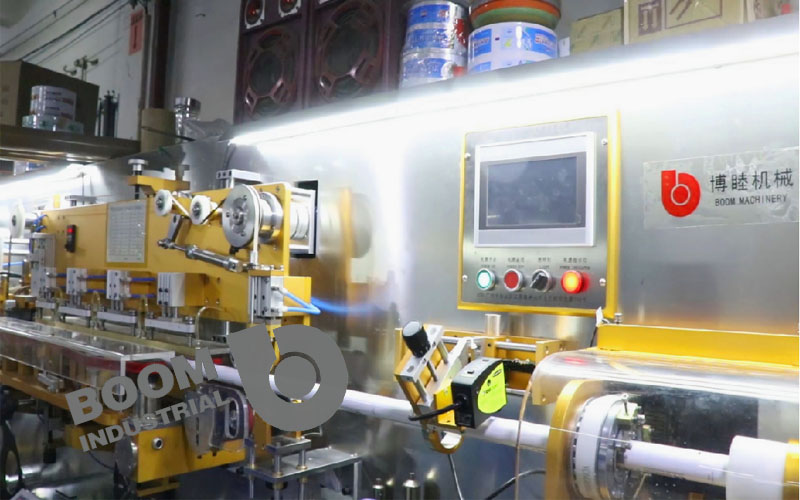

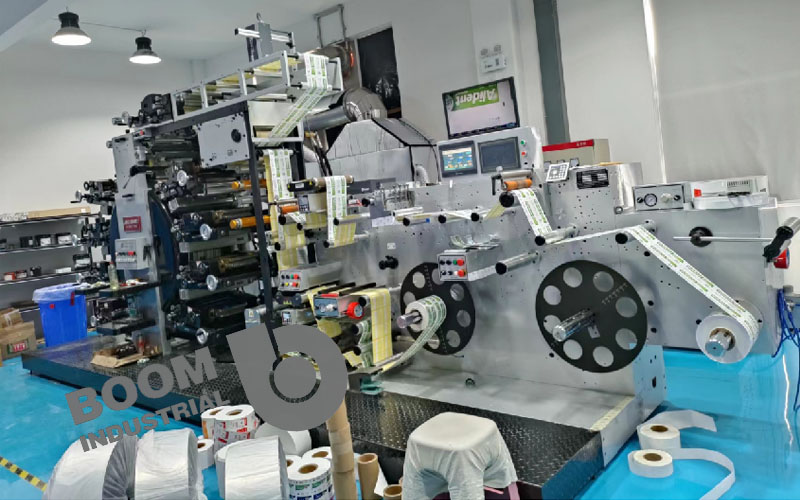

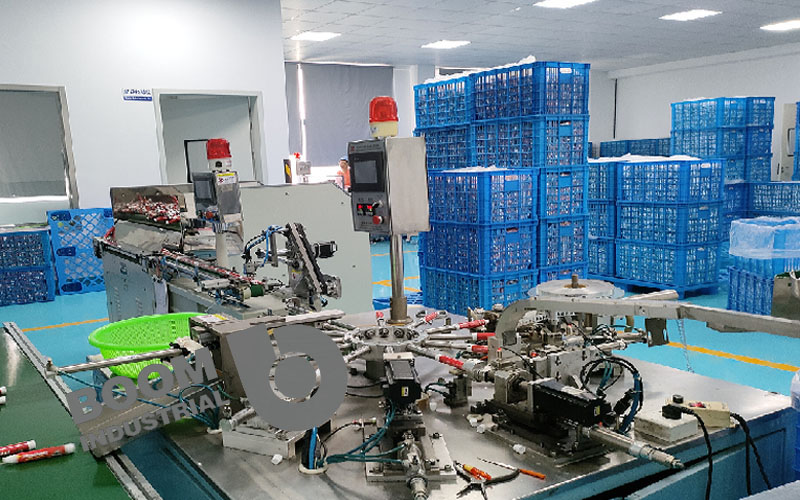

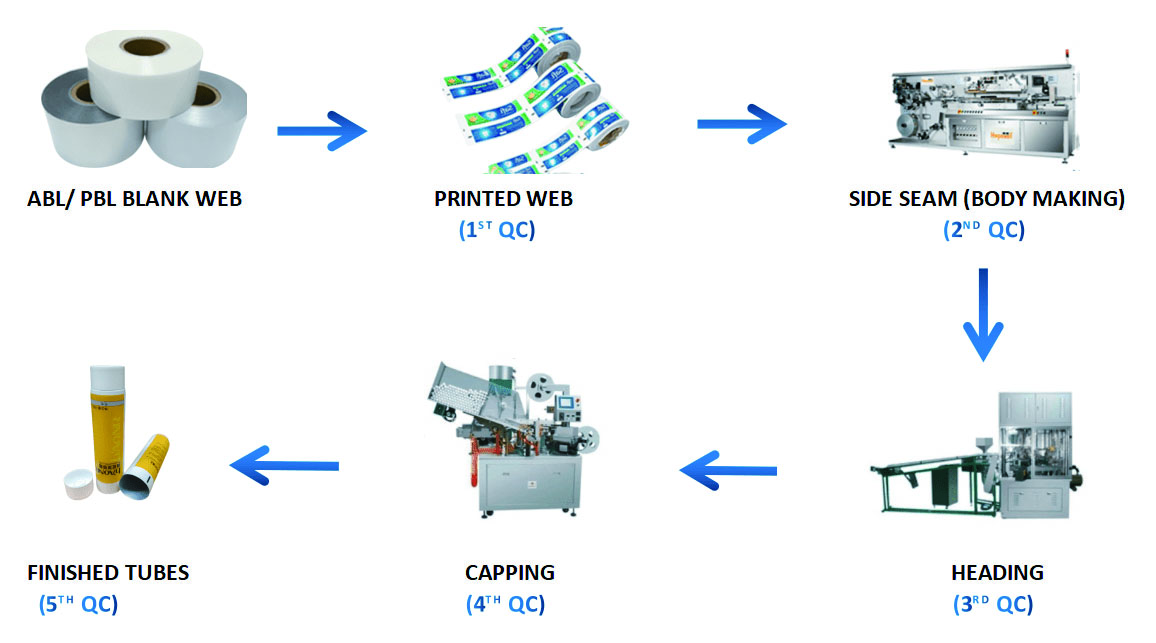

Laminate tubes begin as flat web stock, manufactured by the leading global

suppliers. The tube is then printed to your exact specifications on the

finest quality letterpress or rotogravure equipment. The printed web is

formed into a tubular shape and cut to the desired length to become a

“sleeve.” It is then “headed” and joined with a molded shoulder.

Laminate Tube

Specifications

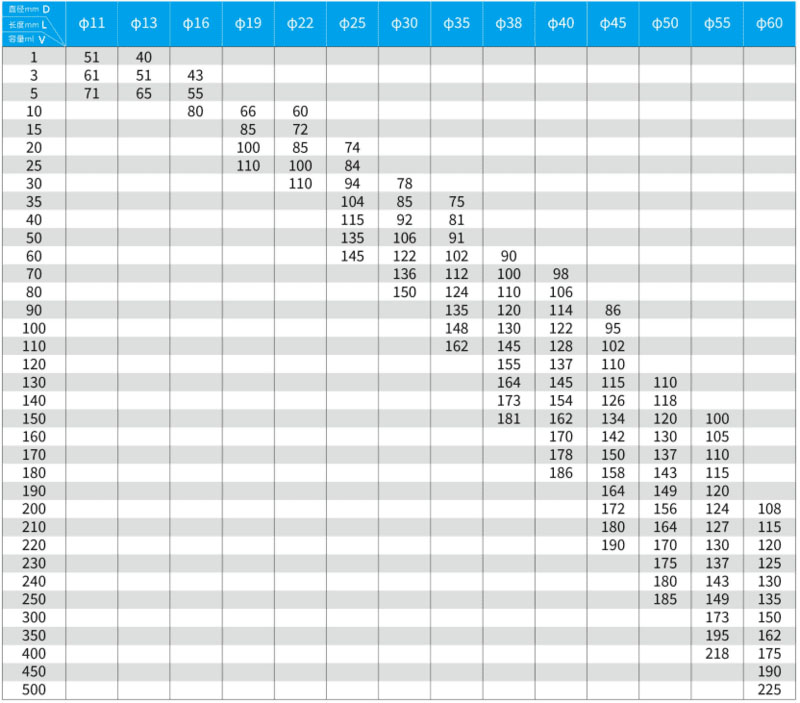

- Diameter: from 11-60mm.

- Volume: from 3ml- 500ml, according to

your requirements. - Caps: PP cap (flip cap or screw cap,

with different styles and colors.) - Tube Shape: Round/ Oval

- Color: Usually 4-8 colors

- Printing: Offset/ Silk Screen/ Hot

Stamping/ UV - Surface Finish: Gloss, Matt

Workshop Environment